Forging the Future: Enhancing Steel Construction with SolidWorks and AI Integration

In the dynamic world of steel construction, the fusion of cutting-edge technologies has paved the way for unprecedented advancements. Among the frontrunners in this convergence is SolidWorks, a powerful 3D modeling software, paired with the transformative potential of Artificial Intelligence (AI). This integration is reshaping the landscape of steel construction, driving efficiency, precision, and innovation to new heights.

Empowering Steel Construction with SolidWorks

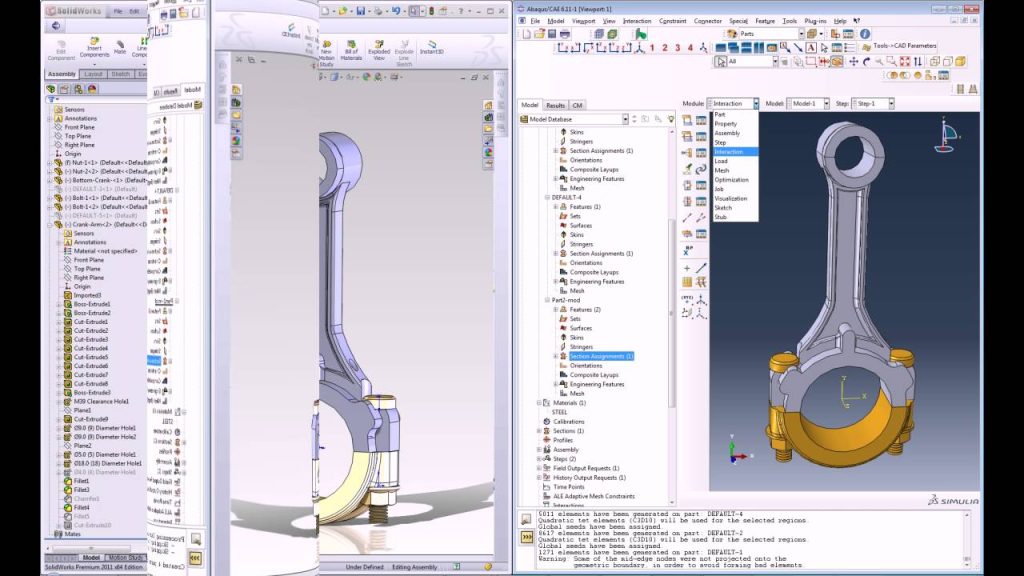

SolidWorks has emerged as a cornerstone in the design and engineering phases of steel construction. This software offers a comprehensive suite of tools that enable architects, engineers, and designers to create intricate and precise 3D models of steel structures.

Design Precision and Visualization: SolidWorks provides a virtual canvas for architects and engineers to bring their visions to life. Its 3D modeling capabilities enable detailed visualizations of steel constructions, allowing stakeholders to better understand and communicate design concepts. This visual clarity helps identify potential design flaws early in the process, leading to more efficient revisions and minimizing costly errors during construction.

Structural Analysis: SolidWorks is equipped with simulation features that facilitate structural analysis. Engineers can subject steel components to various forces, loads, and environmental conditions, gauging their performance under real-world scenarios. This data-driven approach ensures that steel structures are not only visually impressive but also structurally sound and capable of withstanding the challenges they’ll face in their operational lifetimes.

Collaboration and Iteration: The collaborative nature of SolidWorks streamlines communication among project stakeholders. Architects, engineers, and construction teams can work in tandem, exchanging ideas, and iterating on designs in real-time. This synergy reduces misunderstandings and delays, ensuring that the final construction aligns with the initial vision.

AI-Powered Enhancements to SolidWorks

The integration of AI with SolidWorks introduces a new dimension of capabilities that propel steel construction into the future.

Design Optimization: AI algorithms can analyze design variations, taking into account factors such as load distribution, material properties, and cost considerations. By sifting through countless permutations, AI assists designers in identifying the most efficient and cost-effective configurations for steel structures.

Generative Design: AI-driven generative design takes creativity to the next level. By inputting design goals and constraints, AI algorithms generate a range of innovative design options that humans might not have considered. This approach opens doors to novel architectural concepts and efficient structural solutions.

Predictive Analysis: AI can harness historical and real-time data to predict potential issues in steel construction projects. By analyzing factors such as weather conditions, resource availability, and past project outcomes, AI enhances project management, allowing teams to proactively address challenges before they escalate.

Risk Mitigation: AI algorithms can assess potential risks in steel construction projects, offering insights into possible bottlenecks, delays, or budget overruns. This foresight empowers project managers to develop contingency plans and make informed decisions to keep projects on track.

The Future of Steel Construction with SolidWorks and AI

The integration of SolidWorks and AI represents a remarkable synergy of technology and creativity. As AI continues to evolve, its role in optimizing design, predicting outcomes, and enhancing collaboration will become even more pronounced. Steel construction projects, bolstered by these technological advancements, will stand as testaments to human ingenuity, precision engineering, and the transformative power of innovation.